Characteristics of NdFeB Magnet and Its Processing Technology

NdFeB magnetic material, as the latest development of rare earth permanent magnet materials, due to its excellent magnetic properties and known as the "magnetic king." NdFeB magnetic material is neodymium, iron oxide and other alloys. Also known as magnets. NdFeB has a very high energy product and force, while the advantages of high-energy density NdFeB permanent magnetic materials in modern industrial and electronic technology has been widely used, so that the instrumentation, electro-acoustic motor, magnetic magnetization And other equipment, miniaturization, lightweight, thin possible. NdFeB advantage of cost-effective, with good mechanical properties; the inadequacy of the Curie temperature is low, the temperature characteristics of poor, and easy to powder corrosion, must be adjusted by the chemical composition and surface treatment methods to make it improved , In order to achieve the practical application requirements.

The third generation of rare earth permanent magnet NdFeB is the most powerful magnet in contemporary magnet, its main raw materials are rare earth metal neodymium 29% -32.5% metal element iron 63.95-68.65% non-metallic element boron 1.1-1.2% Dysprosium 0.6-1.2% niobium 0.3-0.5% aluminum 0.3-0.5% copper 0.05-0.15% and other elements.

NdFeB permanent magnet material is based on intermetallic compounds RE2FE14B permanent magnet materials. The main components are rare earth (Re), iron (Fe), boron (B). (Dy), praseodymium (Pr) and other rare earth metals, iron can also be cobalt (Co), aluminum (Al) and other metal parts of the alternative, boron content is small, but the rare earth ND But plays an important role in the formation of intermetallic compounds with tetragonal crystal structure, so that the compounds have high saturation magnetization, high uniaxial anisotropy and high Curie temperature.

Process: Ingredients → smelting ingot / rejection with → milling → pressure type → sintered tempering → magnetic detection → grinding processing → pin cutting → plating → finished. Which is the basis of ingredients, sintering tempering is the key.

NdFeB magnet production tools and performance testing tools: smelting furnace, with rejection furnace, E broken machine, air mill, pressing machine, vacuum packaging machine, isostatic press, sintering furnace, heat treatment vacuum furnace, magnetic performance test Instrument, Gauss meter.

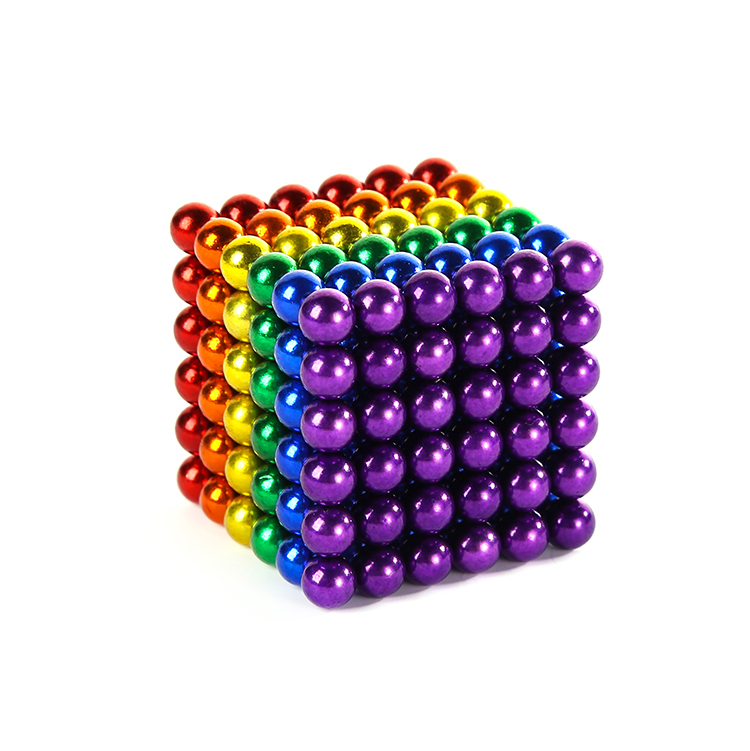

NdFeB magnet machining tool: centerless grinding, spheronization machine, double-end mill, flat grinding, slicing machine, double-sided grinding, wire cutting, Tianjin high-speed, West Lake bench drill.